Plastic Fabrication

At Vaplas, we specialise in providing plastic fabrication and tanks. Whether you require repairs to damaged pipework systems and tanks or new plastic fabrication and tanks, you can be sure of high quality service every step of the way with Vaplas. No matter the shape, size or desired applications of your plastic fabrication, you can be confident that we can provide you with the most appropriate solution that is tailored to your bespoke needs.

Plastic fabrication is an advanced process that bends a thick sheet of plastic into a specified shape by applying heat. Holes and bosses can also be applied for potential lids, handles, axes, hose access, temperature probes and heating elements. We pride ourselves on being able to efficiently cut, drill, rout, polish, bend, mould, bevel, turn, stick and shape large rigid sheets of plastic into amazing designs and displays that our customers can use all over the world.

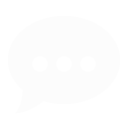

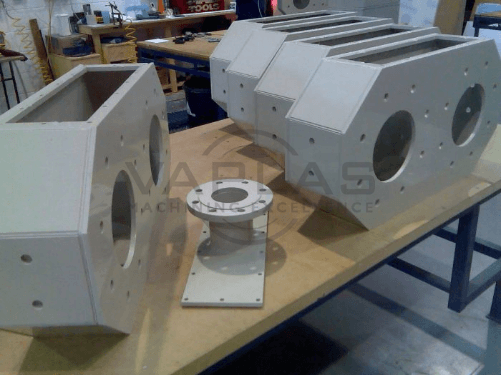

Looking for inspiration? Over many years, we have enabled a wide range of customer designs using plastic fabrication. Typical fabrication projects have included bespoke polypropylene and polyethylene products, machine guards, perspex display cases, control panels, equipment housings, amongst many more.

Some common plastic fabrication techniques include:

- Cutting: Using saws, lasers, or other cutting tools to cut plastic sheets or blocks into specific shapes and sizes.

- Shaping: Using heat or pressure to mold plastic materials into desired shapes and configurations.

- Joining: Bonding plastic materials together using adhesives, welding, or mechanical fasteners.

- Finishing: Applying surface finishes, such as polishing or coating, to improve the appearance or functionality of plastic components.

Plastic fabrication can include a wide range of applications, from creating simple household items to complex industrial components. It can also be used to produce a variety of products, including signs, displays, housings, enclosures, and machine parts. It is a versatile manufacturing process that can accommodate a range of plastic materials, such as acrylic, polycarbonate, PVC, and HDPE.

Overall, plastic fabrication is an important manufacturing process that enables the creation of a wide variety of plastic products and components for various industries, including automotive, aerospace, medical, and consumer products.

Fabricating Plastic

Plastic has a low melting point which means that the material has high flexibility. This allows plastic to be easily formed into simple and complex geometries without any unnecessary stress and strain. Fabricating plastics can result in reduced finishing. Plastic has a high chemical resistance as plastics are generally less likely to suffer damage from chemicals or chemical reactions, such as oxidation or rusting, than metals.

Unlike most metals, plastics can be coloured before fabrication, eliminating any post-treatment processes, such as painting. This helps to lower production costs and in turn customer costs. Fabricating plastics can help to generate rapid productivity, thanks to the quick cycle times and fast turnover rates of fabricating plastics.

How do you maintain quality whilst keeping costs down? Using thermoplastic fabrications, PVC, Polypropylene, Polyethylene, Polycarbonate, Perspex and PETG ensures that our clients receive the highest quality service and products.

Our experienced team of experts are highly-trained to closely monitor the quality of their work to ensure every order is complete and fulfilled to the highest standards in a cost-effective manner. We can manufacture plastic fabrication and tanks in a diverse range of sizes and materials, which can be designed to your unique requirements.

Plastic Fabricated Tanks

Plastic fabricated tanks are designed to store a broad range of substances with many potential use cases. Our tanks have a range of possible applications but are particularly suited to chemical and water processing for short or long-term contracts.

What are the benefits of plastic fabricated tanks?

- Lower cost

- Lightweight: plastic weighs less than metal counterparts

- Easy and hassle-free installation

- Lower maintenance costs

- Quicker tank fabrication

- Transparent plastic allows workers to effortlessly monitor material levels within tank

- Long-lasting service life of at least 20 years or more

For more information, please feel free to call our expert team now on 01924 220 050 to resolve any queries that you may have.

Contact us today?

We are happy to answer any questions you may have on the different plastic machining processes that we use, or even give you a quote on the work you would like to be carried out.

Ask us about machining aluminium too.

Call now on 01924 220 050 and one of our friendly and knowledgeable team will gladly answer any queries you may have.

Contact Details

Unit 6 Tuscany Court

Express Way

Normanton

West Yorkshire

WF6 2AE

P: 01924 220 050

E: sales@vaplas.com