Quality and Service

Vaplas works hard to deliver quality pieces of machined parts to all our customers whilst also delivering a top quality customer service experience too.

Your customer journey with Vaplas may start here on the website, over the phone or maybe you’ve called in to see us on your way past. Either way, you’ll eventually speak to one of our friendly, knowledgeable team in the office to discuss your requirements. With decades of experience under our belts within the plastics industry, we are well equipped with great knowledge on which materials may best suit your requirements and which machining techniques to use to get the best quality, price and speed for your job.

–

The Team

Jason Howell – Managing Director

Dave (Tony) Winter – Sales and Estimating Manager

Darren Thompson – Sales and Estimating

Niki Taylor – Sales and Estimating

Jaimie Leigh Farrand – Administration and Sales Support

How do Vaplas ensure we manufacture and deliver quality parts?

- Stringent Quality Inspection Procedures

Working as a team we are always working on our inspection procedures to ensure everyone from the Machine Operator, to the Inspector knows what each finished piece should look like. We work to set tolerances as a guide and have firm check policies on how many per batch are tested during the manufacturing process, using various different types of measuring equipment to verify each dimension.

Certification

View PDF

Faro Arm

FARO® is the world’s most trusted source for 3D measurement, imaging and realisation technology. The company develops and manufactures leading edge solutions that enable high-precision 3D capture, measurement and analysis across a variety of industries including manufacturing, construction, engineering and public safety.

- Enabling faster, more accurate, compelling and useable 3D documentation

- Accelerating execution timelines

- Minimizing in field 3D documentation and measurement time

- Shrinking margin impacting scrap and rework costs

- Reducing development risk

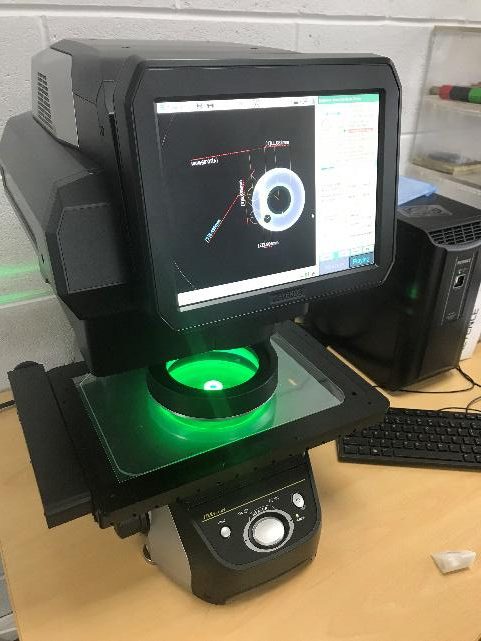

Keyence

Vaplas continues to re-invest with new inspection machinery to assist and improve our already stringent quality procedures.

The new Keyence Image Dimension Measurement System will provide enhanced quality controls at Vaplas by using automatic data recording and delivering inspection reports with the touch of a button. The machine is able to measure up to 99 dimensions in seconds.

With such quick and accurate inspection times this piece of equipment is sure to increase Vaplas’s productivity and output whilst still ensuring the customer gets their perfect parts within the set tolerances.

Providing consistent results is another benefit of this state of the art machinery which will help keep Vaplas at the top of our game.

External Micrometres

Outside Micrometres are used for measuring the thickness or outside diameter of small parts.

Pin Gauges

At Vaplas we machine a lot of parts with small holes in them, we use pin gauges to measure the diameter and accuracy of these holes. They can also be used as a test bar for geometric deviations.

Bowers Analogue Bore Gauges

We use a variety of Bowers XT Analogue Bore Gauges. They are an economical shop floor solution to accurately check bore measurement. The extended mechanical travel of these advanced two or three point gauges ensures that exchanging measuring anvils is now unnecessary. Their wide application range, 2-300mm, rugged construction and easy read scale, ensure both accuracy and ease of use. XT measuring heads and setting rings are supplied with UKAS certification.

You can be sure that when you contact Vaplas with your requirements, the job in hand will be looked after from start to finish by our team of professional staff and equipment.

Contact us today?

We are happy to answer any questions you may have on the different plastic machining processes that we use, or even give you a quote on the work you would like to be carried out.

Ask us about machining aluminium too.

Call now on 01924 220 050 and one of our friendly and knowledgeable team will gladly answer any queries you may have.

Contact Details

Unit 6 Tuscany Court

Express Way

Normanton

West Yorkshire

WF6 2AE

P: 01924 220 050

E: sales@vaplas.com